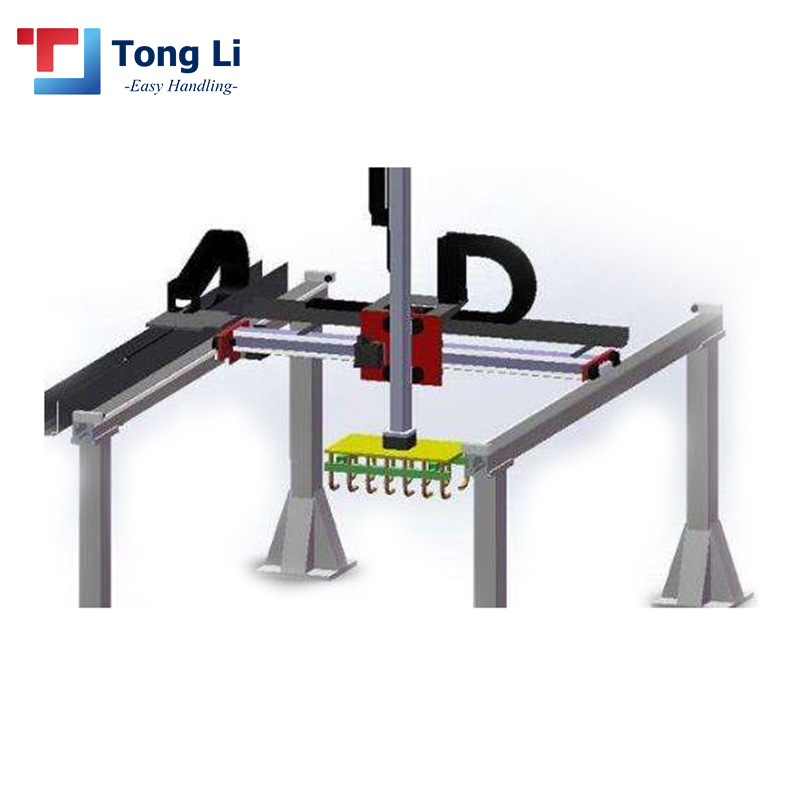

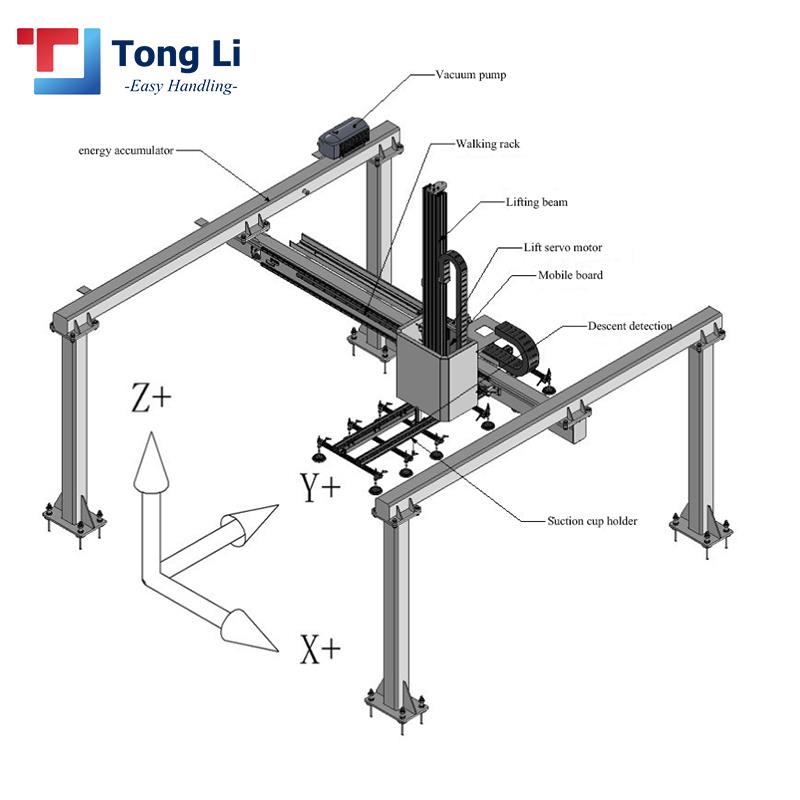

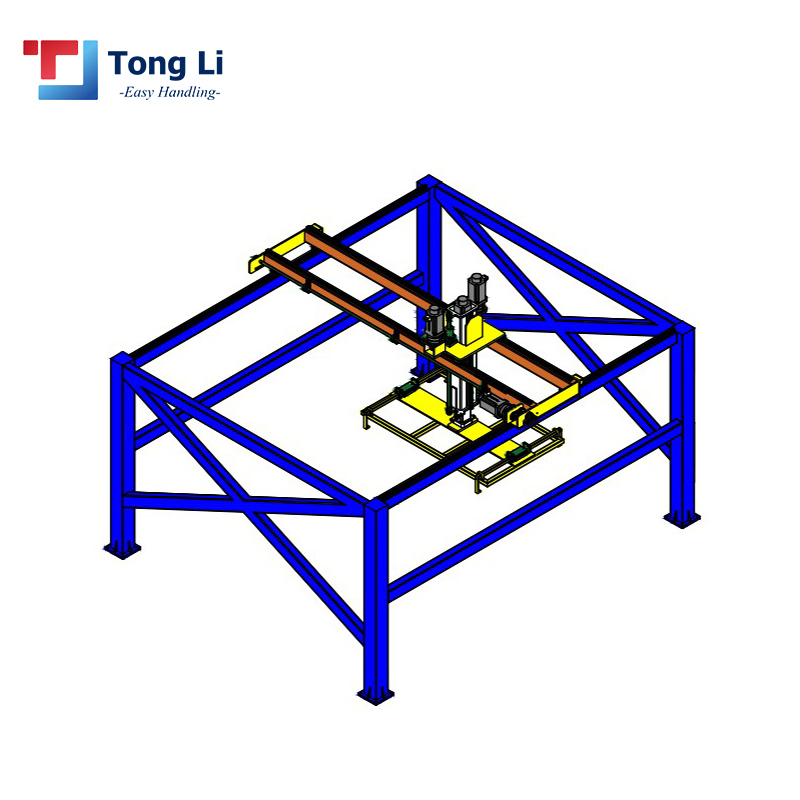

Truss Manipulator

The truss manipulator e sebelisa theknoloji ea ts'ebetso e kopantsoeng, e loketseng ho kenya le ho laolla lisebelisoa tsa mochini le mela ea tlhahiso, phetoho ea mosebetsi, ho potoloha ha mosebetsi, joalo-joalo. ts'ebetso ea othomathiki, le ho pheta-pheta ho nepahala ha maemo ho netefatsa ho nepahala ho phahameng, Ho sebetsa hantle haholo le ho ts'oana ha lihlahisoa tsa batch.

The truss manipulator ke mochini o ka khonang ho bokella lintho tse kenngoeng ka har'a sets'oants'o (joalo ka lebokose, mokotla o lohiloeng, bakete, joalo-joalo) kapa ntho e tloaelehileng e phuthetsoeng le e sa pakeloang.E nka lintho ka bonngoe ka tatellano e itseng ebe e li hlophisa holim'a phalete.Ha ho ntse ho etsoa, lintho li ka kenngoa ka mekhahlelo e mengata 'me li sutumetsoa ka ntle, ho tla ba bonolo ho ea mohato o latelang oa ho paka le ho romela polokelong ea polokelo ka forklift.The truss manipulator e hlokomela tsamaiso e bohlale ea ts'ebetso, e ka fokotsang matla a mosebetsi le ho sireletsa thepa hantle ka nako e le 'ngoe.E boetse e na le mesebetsi e latelang: ho thibela lerōle, ho thibela mongobo, ho thibela letsatsi, ho thibela ho apara nakong ea lipalangoang.Ka hona, e sebelisoa haholo likhoebong tse ngata tsa tlhahiso joalo ka lik'hemik'hale, seno, lijo, biri, polasetiki bakeng sa ho bokella mefuta e fapaneng ea lihlahisoa tsa ho paka joalo ka mabokose, mekotla, makotikoti, mabokose a biri, libotlolo, joalo-joalo.

1. Indasteri ea likarolo tsa likoloi

2. Indasteri ea lijo

3. Indasteri ea thepa

4. Ho sebetsa le ho etsa tlhahiso

5. Indasteri ea koae le joala

6. Indasteri ea ho lokisa lehong

7. Indasteri ea ho sebetsana le lisebelisoa tsa mochine

| Automatic truss manipulator | |||||

| Mojaro (kg) | 20 | 50 | 70 | 100 | 250 |

| Lebelo la mohala | |||||

| X axis (m/s) | 2.3 | 1.8 | 1.6 | 1.6 | 1.5 |

| Y axis (m/s) | 2.3 | 1.8 | 1.6 | 1.6 | 1.5 |

| Z axis (m/s) | 1.6 | 1.3 | 1.3 | 1.1 | 1.1 |

| Sebaka sa mosebetsi | |||||

| X axis (mm) | 1500-45000 | 1500-45000 | 1500-45000 | 1500-45000 | 1500-45000 |

| Y axis (mm) | 1500-8000 | 1500-8000 | 1500-8000 | 1500-8000 | 1500-8000 |

| Z axis (mm) | 500-2000 | 500-2000 | 500-2000 | 500-2000 | 500-2000 |

| Ho nepahala ha maemo a phetoang (mm) | ±0.03 | ±0.03 | ±0.05 | ±0.05 | ±0.07 |

| Sistimi ea ho tlotsa | Setlolo se tsepamisitsoeng kapa se ikemetseng | Setlolo se tsepamisitsoeng kapa se ikemetseng | Setlolo se tsepamisitsoeng kapa se ikemetseng | Setlolo se tsepamisitsoeng kapa se ikemetseng | Setlolo se tsepamisitsoeng kapa se ikemetseng |

| Lebelo le potlakileng (㎡/s) | 3 | 3 | 3 | 2.5 | 2 |